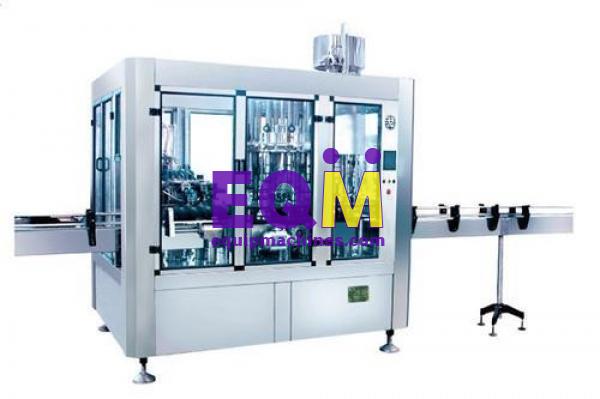

Packing Bottle Liquid Filling Machine

Specification

Machine Type Automatic, Semi-Automatic

Output 2400 to 6000, 3600 to 9000, 5000 to 12000

Direction of Movement Left to Right

Number of Head Syringe 4 Nos, 6 Nos, 8 Nos

Fill Size 5 ml to 1000 ml

Electrical Specs Main Machines 1 HP / 415 Volts / 50 Hz, 1.5 HP / 415 Volts / 50 Hz.

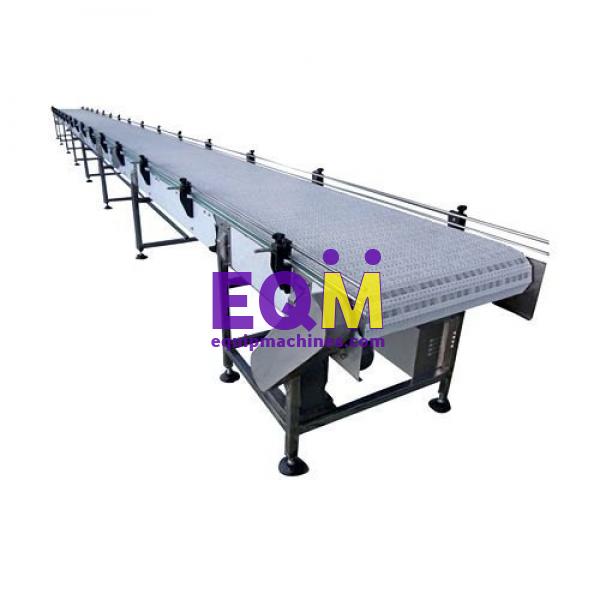

Electrical Specs Main Machines Conveyor 0.5 HP / 415 Volts / 50Hz

Height of Conveyor 860-910 (mm) Adjustable

Change Parts Required (A) Syringes (B) Nozzle (C) Inlet & Outlet Hose Pipe

This versatile unit is suitable for filling various viscosity liquid in to the container.

The unit is consisting of S.S. slat conveyor, reciprocating nozzle with self-cantering devices & S.S. syringe with S.S. body.

Empty containers moving on S.S. slat conveyor, stop through settable twin pneumatically/mechanically operated stopper system below the filling nozzles and meantime container accurately filled by filling nozzle.

The container can be easily and precisely match below the nozzles by help of twin pneumatically operated stopper system and reciprocating nozzles which is avoid spillage of liquid on container. The liquid dose can be easily set by block with a hexagonal bolt fitted below syringes.

Silent Features :

- Rigid vibration free construction, low noise and low power consumption.

- + 1% filling accuracy on single dose.

- Elegant and easy control panel for total control on operation.

- Self lubricating UHMW-PE guide profile for S.S. slat chain provides low friction wear surface, smooth and noiseless conveying.

- Drip tray under the conveyor.

- Pneumatic/Mechanical bottle stopping arrangement.

- safety guard for conveyor gear box, motor and pneumatic cylinders.

- Nitrogen flushing system provided (Pre or Post) as required by customer.

Optional Features :

- Automatic chain washing system for conveyor belt.

- Inbuilt pre-inspection.

- Acrylic cabinet.

- Nitrogen flushing.

- Float tank (Holding tank) with or without stirrer.

Technical Specification :

*Depends on container and label size.

Specification can be altered as per customer specific requirement.